Digital Fabrication of Soft Actuated Objects by Machine Knitting

2019

4D Knitting, knit in motion.

Computationally-controlled machine knitting offers a fabrication technology which can rapidly produce soft textile objects which are breathable, lightweight, and pleasant to the touch. These machines are well established and optimized for the mass production of garments, but compared to other digital fabrication techniques such as CNC machining or 3D printing, they have received much less attention as general purpose fabrication devices. In this work, we explore new ways to employ machine knitting for the creation of actuated soft objects. We describe the basic operation of this type of machine, then show new techniques for knitting tendon-based actuation into objects. We explore a series of design strategies for integrating tendons with shaping and anisotropic texture design. Finally, we investigate different knit material properties, including considerations for motor control and sensing.

This is a collaborative effort between Morphing Matter Lab and Dev Lab at CMU. The knitting was conducted at the CMU Textiles Lab.

By Lea Albaugh, Scott Hudson, Lining Yao

Publications: PDF | DOI

News: Tech Crunch | CMU Homepage | TechXplore

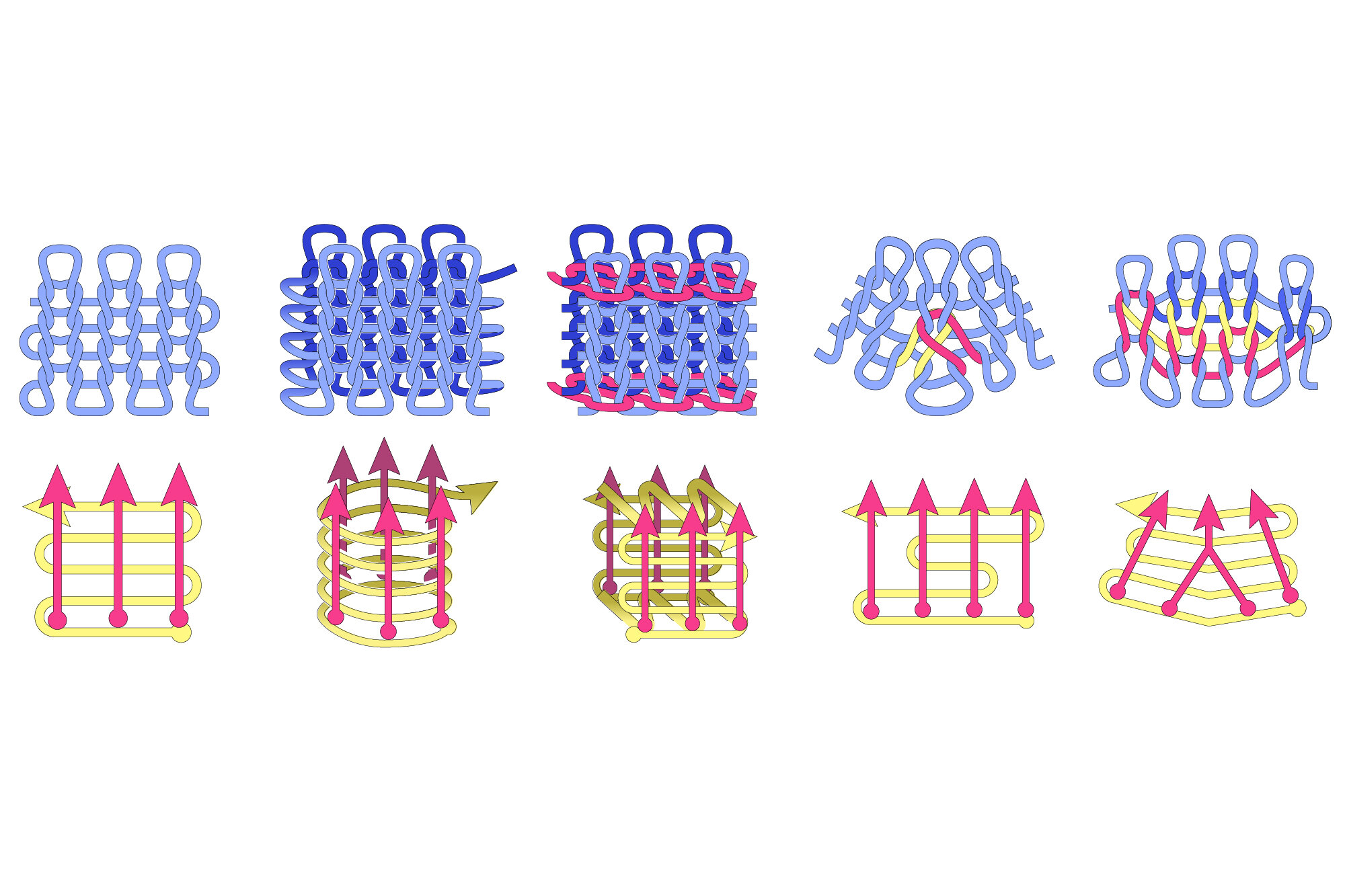

Tendon Techniques: (Left) Inlay technique for embedding horizontal tendons, using needle transfers to interlace a tendon yarn along a row of knitting. (Right) “Tangling” technique for embedding vertical tendons, taking advantage of relative yarn carrier placement while rows are formed to interlace the tendon yarn with different rows of the knitting.

Examples soft artifacts and robots with different tendon distributions that can be achieved by machine knitting.