Morphing Pasta and Beyond

2018-2021

Science Advances 2021 PDF | DOI

By Ye Tao, Yi-Chin Lee, Haolin Liu, Xiaoxiao Zhang, Jianxun Cui, Catherine Mondoa, Mahnoush Babaei, Jasio Santillan, Guanyun Wang, Danli Luo, Di Liu, Humphrey Yang, Youngwook Do, Lingyun Sun, Wen Wang, Teng Zhang, Lining Yao.

The model and simulation were developed by Teng Zhang at Syracuse University.

📣News: New York Times , Science Magzine, Scientific American, Fast Company, National Geographic, PBS, BBC, ABC NEWS, Science Friday, Smithsonian Magzine, Inverse, UK Daily Mail, Science News, Designboom, Yahoo, GIZMODO, TechXpore, physicsworld, NewScientist, cnet | Tracking Live Metrics

🏅 Honors: Cover Story of Science Advances, Fast Company Innovation by Design Award | Creative Food Cycles Honorable Mention Award

Flatpack of morphing pasta for sustainable food packaging and greener cooking

Inspired by how furniture is flat packed to save packaging space and carbon footprint during transportation, we developed a groove-based shape morphing technique that can make many types of materials, especial edible materials such as authentic Italian pasta made of semolina flour and water, flat-packed and morph when cooked.

The plastic material, used in food packaging, is a major contributor to landfills in the United States. Finding effective food packaging strategies is crucial to maintaining a sustainable future. We proposed the design concept of morphing food that can be flat-packed to reduce packing space during transportation and storage.

Universal and simple parametric groove-based morphing mechanism.

Morphing structures are often engineered with stresses introduced into a flat sheet by leveraging structural anisotropy or compositional heterogeneity. However, these mechanisms cannot be applied practically to morphing food, as food material composition is subject to many constraints, associated with nutritional requirements or culinary culture. For example, authentic Italian pasta dough is only supposed to be made of semolina flour and water. In addition, restrictions are also placed on manufacturing techniques due to cost and food safety.

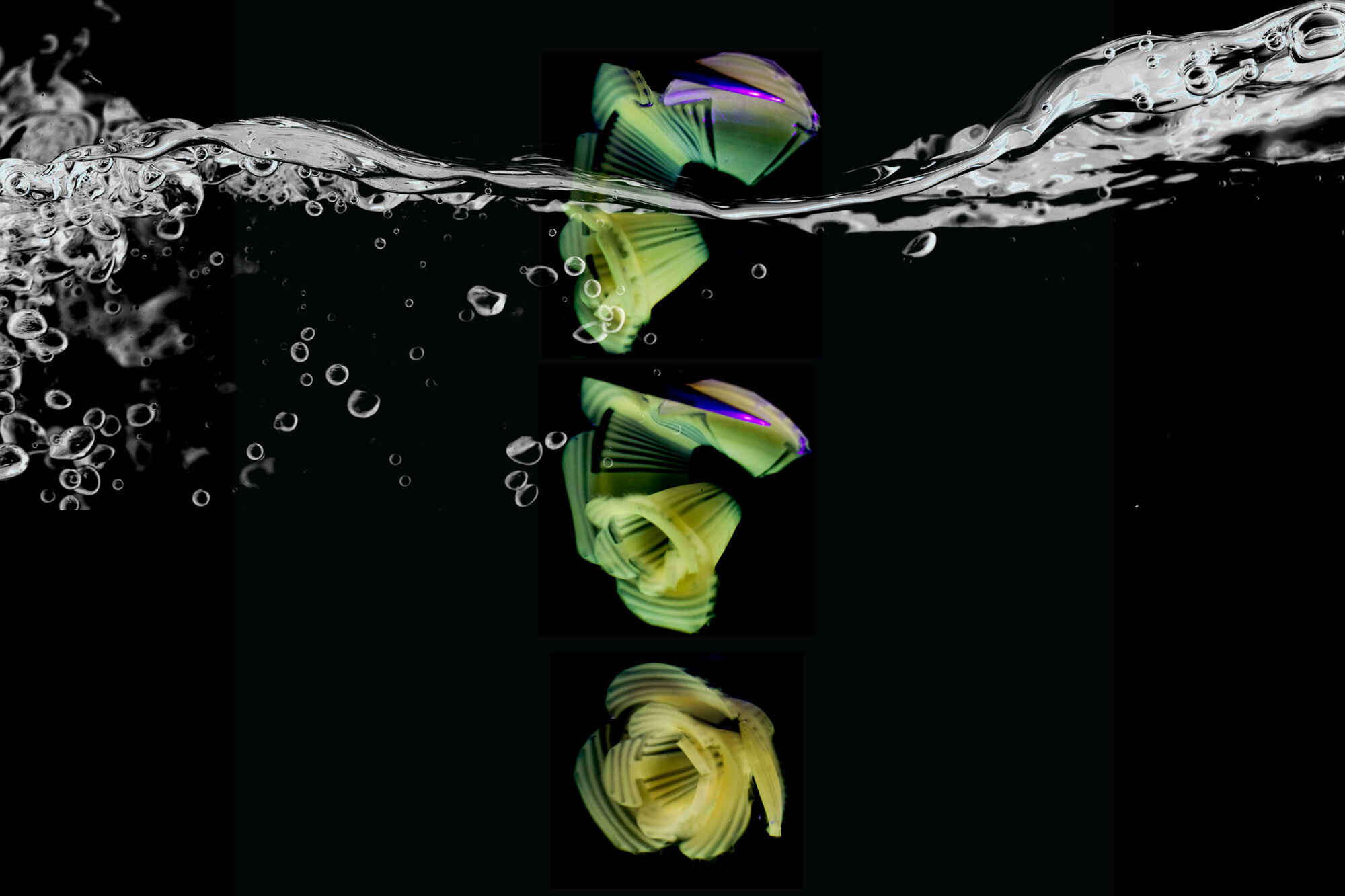

In order to fulfill these functional requirements of food, we introduced a simple and universal diffusion-based mechanism to enable a transient morphing effect in structures with parametric surface grooves. The grooves can be realized with a single material and fabricated using low-cost manufacturing methods, such as stamping, molding, and casting. The authors demonstrate from quantitative experiments and multiphysics simulations that parametric surface grooving can induce temporary asynchronous swelling or deswelling and can transform flat objects into designed, three-dimensional shapes.

For 3D-shaped pasta like macaroni, more than 60% of the packaging space is used to pack air. By making flatpack pasta, we can save a large portion of the packaging space for food.

Our team ran multi-physics simulations on the morphing of pasta dough. The coupling of the diffusion and stiffness changing during the pasta cooking process is a very interesting challenge to solve from a mechanics perspective. The understanding of the transient morphing behavior can be generalized to other engineering materials, such as hydrogel morphing that is widely used in biomedical and soft robotic fields.

Nearly all food morphs during the cooking process. For example, pasta expands and softens as it is boiled due to water diffusion, the relaxation of the macromolecular matrix, and starch gelatinization. Such morphing effects, if engineered properly, could positively impact the food industry, chefs, consumers and the environment. The final shape of food directly affects the eating experience - the mouthfeel, taste, and appearance. The shape of food also has a big impact in sustainability: the team’s work showed novel uses of food morphing to reduce packaging waste through food that is produced and packed in a flat form that can morph into desired shapes upon cooking (i.e., morphing pasta).

Further, the shape of food will also impact the carbon footprint during the cooking process. For example, in Italy, 0.7% to 1% of greenhouse gas emissions is due to cooking pasta, and these emissions could be reduced by half if the shape and cooking processes could be optimized. Flat pasta with surface texture has a larger surface area to volume ratio and can be cooked faster than the ones with an inner cavity (e.g., macaroni).

In their newly published paper titled ‘Morphing Pasta and Beyond’ featured as a cover story in the May issue of Science Advances, the researchers explained the underlining morphing mechanism through quantitative design and analysis. The development of a comprehensive guiding design principle is important for others outside of the scientific field, such as chef and food manufacturers, to create their own unique morphing food with a broadened categories of food materials including different wheat flours, gluten-free materials, and food gels.

We believe the space-saving feature of flat-packed food becomes even more critical for contexts including hiking trips, disaster site food delivery, or space travels. We conducted a field test by carrying and cooking the flat-packed pasta during a hiking trip. We were able to successfully cook the helical morphing pasta with a portable cooker.

The grooves on the surface of the dough are created by either a manual or an automated machine stamping process.

Acknowledgment

We would like to thank our sponsors, including the US National Science Foundation, the Foundation of Natural Science in China, the CMU Future Manufacturing Initiative, as well as a food industry sponsor who graciously supported earlier development in 2018 yet hoped to keep its name confidential.

We would like to thank our MIT colleagues who co-authored an earlier paper titled Transformative Appetite in 2017, which motivated a lot of these ideas proposed here. Back then, we also tightly worked with Target FOOD+FUTURE coLab.

On this project, we also received insightful comments and help from Chengyuan Wei from ETH Zurich, Jack Forman from MIT Media Lab, Jianzhe Gu from our lab, and Professor Eran Sharon from the Hebrew University of Jerusalem.

Finally, we’d like to thank Cindy Chepanoske for her IP support, and Aaron Aupperlee for media.